News

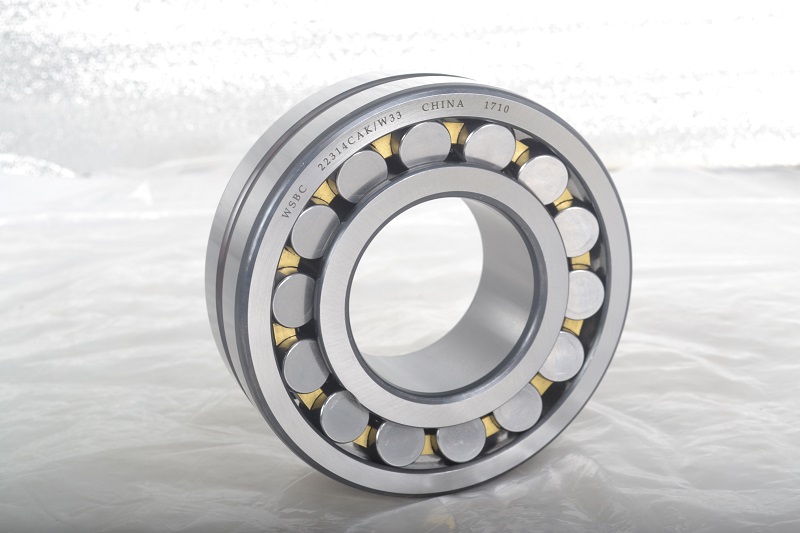

WSBC 22314 CAK/W33 Spherical Roller Bearing: Innovative Design and Robust Performance in Mining Applications

Time:2025.04.18 Source:Roller Bearings Suppliers

The WSBC 22314 CAK/W33 spherical roller bearing, engineered for heavy-duty industrial applications, stands out as a critical component in mining machinery due to its advanced design and ability to withstand extreme operational conditions. Combining high load capacity, self-aligning capabilities, and enhanced durability, this bearing is tailored to meet the rigorous demands of mining equipment such as crushers, vibrating screens, and conveyor systems

Design Features of WSBC 22314 CAK/W33

Self-Aligning Symmetrical Rollers

The bearing features two rows of symmetrical barrel-shaped rollers, optimized for uniform load distribution across the raceways. This design minimizes edge stress concentrations, significantly extending service life even under heavy radial and axial loads

Robust Cage Structure

Utilizing a machined brass cage (CA-type design), the WSBC 22314 ensures superior strength and heat resistance. The cage guides rollers smoothly, reducing friction and wear, particularly in high-vibration environments common in mining operations

Enhanced Lubrication (W33 Designation)

Equipped with a lubrication groove and three oil holes on the outer ring (denoted by the W33 suffix), this bearing facilitates efficient grease replenishment. This feature is critical in dusty mining environments, where contamination resistance and continuous lubrication are paramount

High Tolerance for Misalignment

The spherical outer ring raceway allows up to 2.5 degrees of misalignment compensation, mitigating shaft deflection and housing inaccuracies—common challenges in large-scale mining machinery

Optimized for Vibration Resistance

Designed with reinforced internal geometry and C4 radial clearance, the WSBC 22314 excels in applications involving oscillatory or shock loads, such as vibrating screens and crushers. This reduces the risk of premature failure due to acceleration forces . WSBC 22314 CAK/W33 bearings online , pls click here :

Applications in the Mining Industry

Vibrating Screens and Crushers

In vibrating screens, the bearing’s ability to handle high accelerations (both rotational and linear) ensures stable operation under intense vibration. Its robust construction minimizes downtime caused by roller cage fatigue or lubrication failure

Conveyor Systems

Used in conveyor drive pulleys and idlers, the WSBC 22314 supports heavy radial loads while accommodating shaft misalignment caused by uneven terrain or belt tension fluctuations. The W33 lubrication system further enhances reliability in continuous operation

Ball Mills and Grinding Equipment

The bearing’s high dynamic load rating (Cr) and fatigue resistance make it ideal for grinding machinery, where cyclical loading and abrasive environments demand exceptional durability

Mining Trucks and Shovels

In off-highway trucks, the bearing’s capacity to withstand shock loads and contamination aligns with the harsh conditions of open-pit mining, ensuring longevity in wheel hubs and drivetrain components

Technical Advantages for Mining

Extended Service Life: Advanced heat treatment and material purity (low inclusion steel) enhance resistance to fatigue and surface damage, critical for equipment subjected to 24/7 operation

Sealed Options: Optional contact seals (e.g., 2CS, 2CS2) with oil-resistant elastomers provide additional protection against dust and moisture ingress, reducing maintenance frequency

Ease of Installation: Tapered bore variants (suffix K) simplify mounting on cylindrical shafts using adapter sleeves, a practical feature for field maintenance in remote mining sites

As mining operations push toward higher efficiency and automation, bearings like the WSBC 22314 CAK/W33 are evolving to integrate smart monitoring systems. Future iterations may embed sensors for real-time health tracking, enabling predictive maintenance and reducing unplanned downtime

The WSBC 22314 CAK/W33 exemplifies innovation in spherical roller bearing technology, delivering unmatched performance in the mining sector. Its design harmonizes load capacity, durability, and adaptability, making it a cornerstone for machinery that drives productivity in one of the world’s most demanding industries.

Hot Topics

Copyright © Wuxi Spark Bearings Co.,Ltd Co., Ltd All Rights Reserved. Sitemap

www.spark-bearing.com. Profession in Roller Bearings, Ball Bearings and Taper Toller Bearings-China Suppliers.